HOW TO PROTECT YOUR SOLAR POWER SYSTEM FROM LIGHTNING

Lightning is a common cause of failures in photovoltaic (PV) and wind-electric systems. A damaging surge can occur from lightning that strikes a long distance from the system, or even between clouds. But most lightning damage is preventable. Here are some of the most cost-effective techniques that are generally accepted by power system installers, based on decades of experience. Follow this advice, and you have a very good chance of avoiding lightning damage to your renewable energy (RE) system.

Get Grounded

Grounding is the most fundamental technique for protection against lightning damage. You can’t stop a lightning surge, but you can give it a direct path to ground that bypasses your valuable equipment, and safely discharges the surge into the earth. An electrical path to ground will constantly discharge static electricity that accumulates in an aboveground structure. Often, this prevents the attraction of lightning in the first place.

Lightning arrestors and surge protectors are designed to protect electronic equipment by absorbing electrical surges. However, these devices are not a substitute for good grounding. They function only in conjunction with effective grounding. The grounding system is an important part of your wiring infrastructure. Install it before or while the power wiring is installed. Otherwise, once the system is working, this important component may never get checked off on the “to do” list.

Step one in grounding is to construct a discharge path to ground by bonding (interconnecting) all the metal structural components and electrical enclosures, such as PV module frames, mounting racks, and wind generator towers. The National Electrical Code (NEC), Article 250 and Article 690.41 through 690.47 specify code-compliant wire sizes, materials, and techniques. Avoid sharp bends in ground wires—high current surges don’t like to turn tight corners and can easily jump to nearby wiring. Pay special attention to attachments of copper wire to aluminum structural elements (particularly the PV module frames). Use connectors labeled “AL/CU” and stainless steel fasteners, which reduce the potential for corrosion. The ground wires of both DC and AC circuits will also be connected to this grounding system. (Refer to Code Corner articles on PV array grounding in HP102 and HP103 for more advice.)

Ground Rods

Ground Rods

The weakest aspect of many installations is the connection to the earth itself. After all, you can’t just bolt a wire to the planet! Instead, you must bury or hammer a rod of conductive, noncorrosive metal (generally copper) into the ground, and make sure most of its surface area contacts conductive (that means moist) soil. This way, when static electricity or a surge comes down the line, the electrons can drain into the ground with minimal resistance.

In a similar way to how a drain field dissipates water, grounding acts to dissipate electrons. If a drainpipe doesn’t discharge adequately into the ground, backups occur. When electrons back up, they jump the gap (forming an electrical arc) to your power wiring, through your equipment, and only then to ground.

To prevent this, install one or more 8-foot-long (2.4 m), 5/8-inch (16 mm) copper-plated ground rods, preferably in moist earth. A single rod is usually not sufficient, especially in dry ground. In areas where the ground gets extremely dry, install several rods, spacing them at least 6 feet (3 m) apart and connecting them together with bare copper wire, buried. An alternate approach is to bury #6 (13 mm2), double #8 (8 mm2), or larger bare copper wire in a trench at least 100 feet (30 m) long. (The bare copper ground wire also can be run along the bottom of a trench that carries water or sewer pipes, or other electrical wires.) Or, cut the ground wire in half and spread it in two directions. Connect one end of each buried wire to the grounding system.

Try to route part of the system into wetter areas, like where a roof drains or where plants are to be watered. If there is steel well-casing nearby, you can use it as a ground rod (make a strong, bolted connection to the casing).

In moist climates, the concrete footers of a ground- or pole-mounted array, or a wind generator tower, or ground rods encased in concrete will not provide ideal grounding. In these locations, concrete will typically be less conductive than the moist soil surrounding the footings. If this is the case, install a ground rod in earth next to the concrete at the base of an array, or at the base of your wind generator tower and at each guy wire anchor, then connect them all together with bare, buried wire.

In dry or arid climates, the opposite is often true— concrete footings may have a higher moisture content than the surrounding soil, and offer an economical opportunity for grounding. If 20-foot-long (or longer) rebar is to be embedded in concrete, the rebar itself can serve as a ground rod. (Note: This must be planned before the concrete is poured.) This method of grounding is common in dry locations, and is described in the NEC, Article 250.52 (A3), “Concrete-Encased Electrode.”

If you are unsure of the best grounding method for your location, talk with your electrical inspector during the design phase of your system. You cannot have too much grounding. In a dry location, use every opportunity to install redundant ground rods, buried wire, etc. To avoid corrosion, use only approved hardware for making connections to ground rods. Use copper split-bolts to splice ground wires reliably.

Grounding Power Circuits

For building wiring, the NEC requires one side of a DC power system to be connected—or “bonded”—to ground. The AC portion of such a system must also be grounded in the conventional manner of any grid-connected system. (This is true in the United States. In other countries, ungrounded power circuits are the norm.) Grounding the power system is required for a modern home system in the United States. It is essential that the DC negative and the AC neutral are bonded to ground at only one point in their respective systems, and both to the same point in the grounding system. This is done at the central power panel.

Producers of some single-purpose, stand-alone systems (like solar water pumps and radio repeaters) recommend not grounding the power circuit. Refer to the manufacturer’s instructions for specific recommendations.

Array Wiring & “Twisted Pair” Technique

Array wiring should use minimum lengths of wire, tucked into the metal framework. Positive and negative wires should be of equal length, and be run together whenever possible. This will minimize induction of excessive voltage between the conductors. Metal conduit (grounded) also adds a layer of protection. Bury long outdoor wire runs instead of running them overhead. A wire run of 100 feet(30 m) or more is like an antenna—it will receive surges even from lightning in the clouds. Similar surges can still occur even if the wires are buried, but most installers agree that buried transmission wiring further limits the possibility of lightning damage.

A simple strategy to reduce susceptibility to surges is the “twisted pair” technique, which helps equalize and cancel out any induced voltages between the two or more conductors. It can be difficult to find suitable power cable that is already twisted, so here’s what to do: Lay out a pair of power wires along the ground. Insert a stick between the wires, and twist them together. Every 30 feet (10 m), alternate the direction. (This is much easier than trying to twist the whole distance in one direction.) A power drill can sometimes be used to twist wiring as well, depending on the wire size. Just secure the ends of the wiring into the drill’s chuck and let the drill’s action twist the cables together. Make sure to run the drill at the lowest possible speed if you try this technique.

The ground wire need not be twisted with the power wires. For burial runs, use bare copper wire; if you use conduit, run the ground wire outside the conduit. The additional earth contact will improve the grounding of the system.

Use twisted-pair cable for any communication or control cables (for example, a float-switch cable for full-tank shutoff of a solar water pump). This smaller gauge wire is readily available in pre-twisted, multiple, or single pair cables. You also can purchase shielded twisted-pair cable, which has a metallic foil surrounding the twisted wires, and typically a separate, bare “drain” wire as well. Ground the cable shield and drain wire at one end only, to eliminate the possibility of creating a ground loop (less direct path to ground) in the wiring.

Additional Lightning Protection

In addition to extensive grounding measures, specialized surge protection devices and (possibly) lightning rods are recommended for sites with any of the following conditions:

• Isolated location on high ground in a severe lightning area

• Dry, rocky, or otherwise poorly conductive soil

• Wire runs longer than 100 feet (30 m)

Lightning Arrestors

Lightning (surge) arrestors are designed to absorb voltage spikes caused by electrical storms (or out-of-spec utility power), and effectively allow the surge to bypass power wiring and your equipment. Surge protectors should be installed at both ends of any long wire run that is connected to any part of your system, including AC lines from an inverter. Arrestors are made for various voltages for both AC and DC. Be sure to use the appropriate arrestors for your application. Many system installers routinely use Delta surge arrestors, which are inexpensive and offer some protection where the threat of lightning is moderate, but these units are no longer UL listed.

PolyPhaser and Transtector arrestors are high quality products for lightning-prone sites and larger installations. These durable units offer robust protection and compatibility with a wide variety of system voltages. Some devices have indicators to display failure modes.

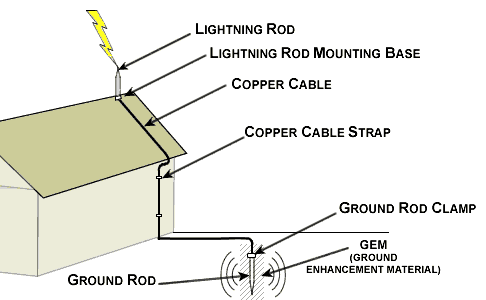

Lightning Rods

“Lightning rods” are static discharge devices that are placed above buildings and solar-electric arrays, and connected to ground. They are meant to prevent the buildup of static charge and eventual ionization of the surrounding atmosphere. They can help prevent a strike, and can provide a path for very high current to ground if a strike does occur. Modern devices are spike-shaped, often with multiple points.

“Lightning rods” are static discharge devices that are placed above buildings and solar-electric arrays, and connected to ground. They are meant to prevent the buildup of static charge and eventual ionization of the surrounding atmosphere. They can help prevent a strike, and can provide a path for very high current to ground if a strike does occur. Modern devices are spike-shaped, often with multiple points.

Lighting rods are typically only used at sites that experience extreme electrical storms. If you think your site falls into this category, hire a contractor who has experience in lightning protection. If your system installer is not so qualified, consider consulting with a lightning protection specialist before the system is installed. If possible, select a North American Board of Certified Energy Practitioners (NABCEP) certified PV installer (see Access). Although this certification isn’t specific to lightning protection, it can be an indication of an installer’s level of overall competence.

Out of Sight, Not Out of Mind

A lot of lightning protection work is buried, and out of sight. To help ensure that it gets done correctly, write it into your contract(s) with your system installer, electrician, excavator, plumber, well driller, or anyone who is doing earthwork that will contain your grounding system.